Chino Desalter Integration Services

The Chino Basin Desalter Authority added a new reverse osmosis (RO) train to their facility in Ontario, California. The existing SCADA system needed to be updated with new controls and visibility for the new RO train. The SCADA system was partially commissioned by another integrator, but the commissioning process was not executed in an expeditious or quality manner. Cannon was selected to evaluate the status, recommend a path to completion, and complete the commissioning of the SCADA system associated with the new RO train. Cannon developed most of the PLC and HMI programming offline and off-site to reduce the number of interruptions to operations. Cannon then downloaded the program into the online controller during a scheduled facility shutdown and worked with District staff to commission the new train.

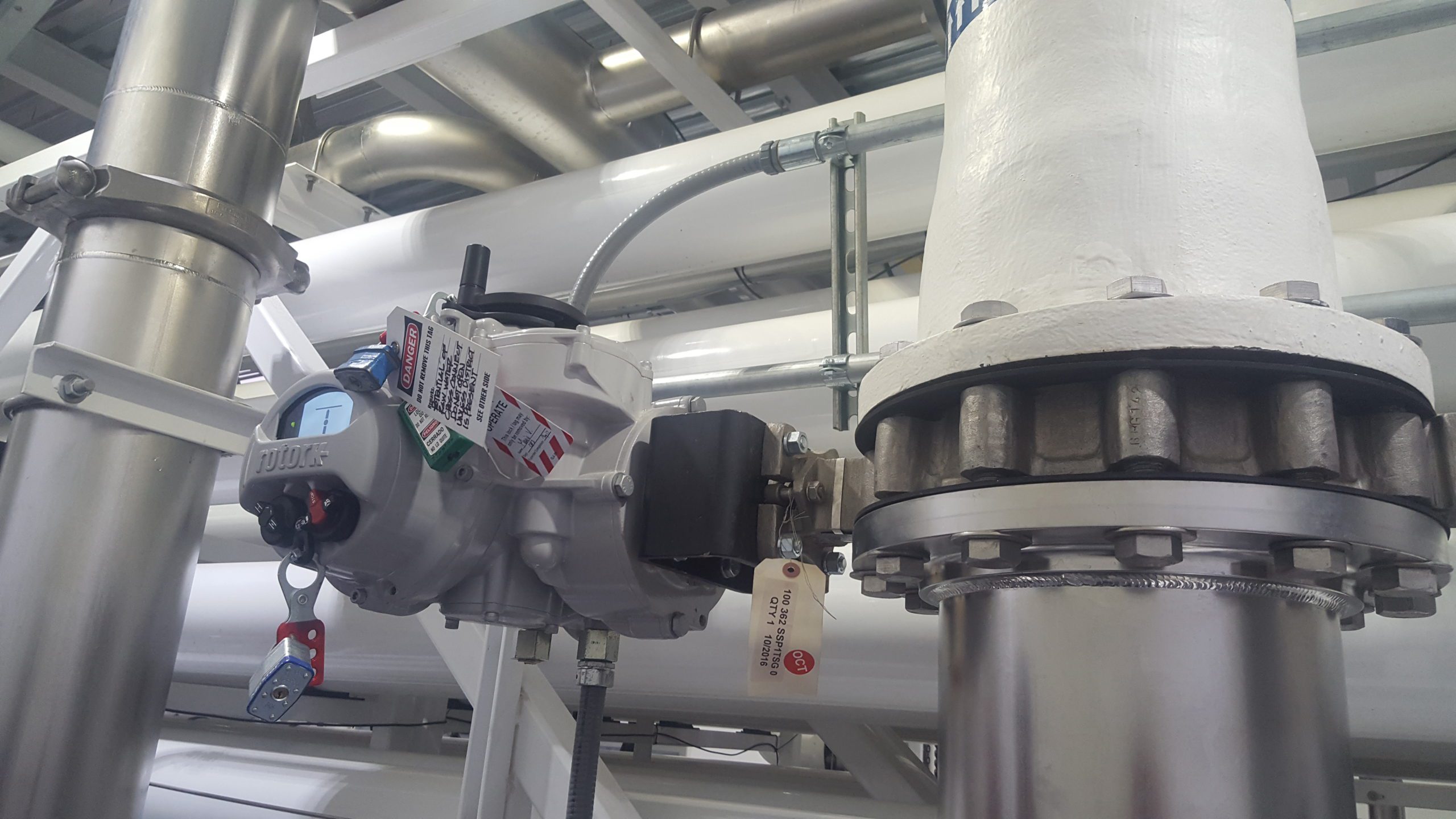

The new RO train control devices consisted of a variable speed feed water pump, a variable speed booster pump with an integrated energy recovery turbine, and Rotork control valves. Instrumentation included pressure, flow, and analytical (pH and conductivity) transmitters. Cannon successfully integrated the new instrumentation and control devices in the existing Quantum PLC and Wonderware application. We also checked and modified the wiring and control loops as needed.

During the delivery of this project, some of the antiquated hardware experienced a fatal failure. Cannon’s delivery method, however, included contingency planning with District staff to identify critical components and processes allowing us to prepare a back-up plan that allowed the system to operate without interruptions. Other challenges included the distinct configuration of the Toshiba variable frequency drives (VFD), the Rotork control valve network, and some discrepancies between the record drawings and the wiring loops.

Many parties were involved with this effort, including the owner and operator, the general contractor, the electrical contractor (U.S. Controls Inc.), the original equipment manufacturer, the Toshiba VFD technician, and the Rotork valves technician. Through collaboration and communication with each party, Cannon successfully commissioned the new train and SCADA system.

Location

Ontario, California

Key Elements

- SCADA

- PLC/HMI Programming

- Startup/Commissioning