Our Solutions Work Smarter

At Cannon, we have built a team capable of handling the electrical, structural, automation, and process design needs at your facility. We can provide streamlined designs and value-added efficiency at every step of the process. Whether you manufacture food, chemicals, or pharmaceuticals, Cannon is here to design a process you can trust.

Why Partner with Cannon?

- Full-service capabilities from electrical to structural to automation to scanning and surveying all in-house.

- Having a collaborative team that works together between electrical, structural, mechanical, chemical disciplines produces better—and more efficient— solutions.

- We’re able to work remotely and cost-effectively anywhere in the country, offering on-site information collection and design.

- Unmatched client service

From feasibility studies to design and integration, Cannon can deliver solutions for your industrial wastewater needs.

- Technology Development and Integration

- Desalination

- Membrane Technology

- Reverse Osmosis

- Electrocoagulation / Electrophoresis

- Recycled Water Systems

Services

- Scope Development and Feasibility Analysis

- Front End Engineering Design (FEED)

- Capacity and Expansion Evaluations

- Engineering and Design

- Automation Design and Programming

- Project Cost Estimating Support

- Permitting and Regulatory Support

- Bid and Procurement Support

- Hydraulic Modeling

- Arc Flash Studies

- Inspection and Leak Detection

- Management of Change (MOC) and Process Hazard Analysis (PHA)

- Construction Management and Field Engineering

- Surveying, Mapping, and Laser Scanning

- Startup, Commissioning, and Testing

More Info

Whether your needs range from process design to facility design, Cannon has the capabilities, knowledge, and experience necessary for a successful, cost-competitive project.

- Process and Facility Design

- International Codes and Standards

- Equipment Design

- Materials Selection and Corrosion Mitigation

Services

- Scope Development and Feasibility Analysis

- Front End Engineering Design (FEED)

- Capacity and Expansion Evaluations

- Engineering and Design

- Automation Design and Programming

- Project Cost Estimating Support

- Permitting and Regulatory Support

- Bid and Procurement Support

- Process Modeling and Simulation

- Arc Flash Studies

- Inspection and Leak Detection

- Support Process Hazard Analysis (PHA) and Hazards and Operability Studies (HAZOP)

- Construction Management and Field Engineering

- Surveying, Mapping, and Laser Scanning

- Startup, Commissioning, and Testing

Having long served the agricultural, viticulture, and brewing industries, Cannon is uniquely equipped to handle your process design, engineering, automation, and electrical needs.

- Agriculture

- Breweries

- Manufacturing

- Wineries

Services

- Scope Development and Feasibility Analysis

- Front End Engineering Design (FEED)

- Capacity and Expansion Evaluations

- Engineering and Design

- Automation Design and Programming

- Process and Facility Design and Review

- Process Optimization

- High Voltage Electrical

- Conveyance Design

- Site Lighting

- Project Cost Estimating Support

- Permitting and Regulatory Support

- Bid and Procurement Support

- Process Modeling and Simulation

- Arc Flash Studies

- Construction Management and Field Engineering

- Surveying, Mapping, and Laser Scanning

- Startup, Commissioning, and Testing

Industrial Projects

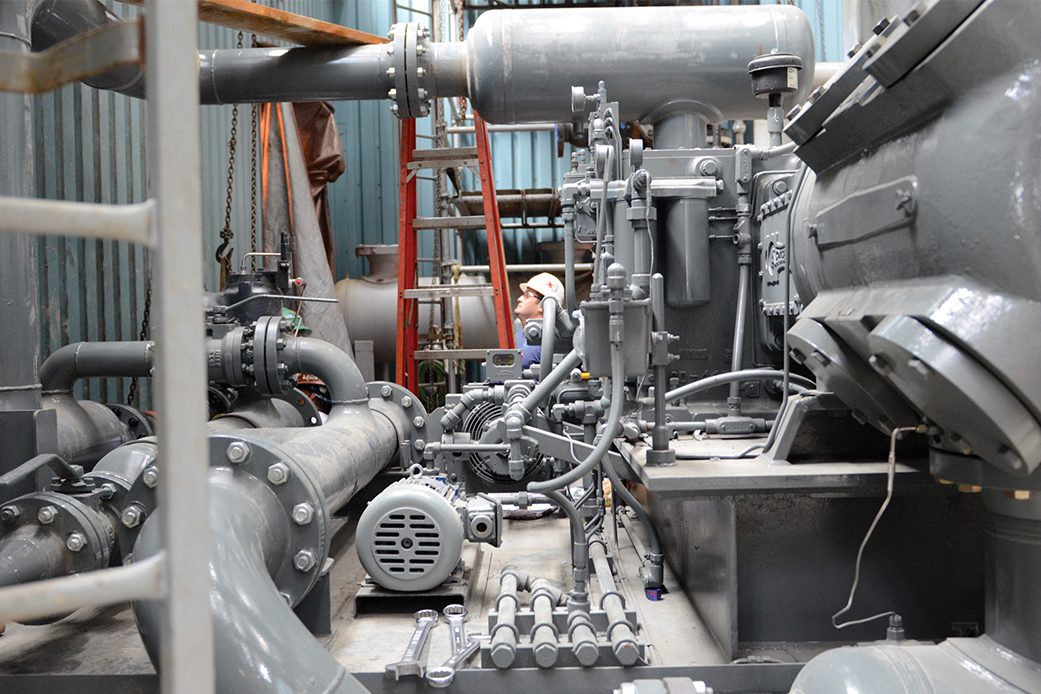

Refining & Chemical Processing

Hydrochloric Acid System

The existing FRP tanks at the Lubrizol Advanced Materials Inc. plant required replacing the plant’s hydrochloric acid scrubbing system. Lubrizol selected Cannon to provide engineering design, plans, and specifications for the new equipment, as well as calculations for secondary containment and specified concrete coating for increased protection.